Heat Recovery VRF

Heat Recovery VRF

-

6 Ton to 10 Ton

VRF

Features

• High Efficiency

• All DC Inverter Technology

• Wide Range of Voltage

• Intelligent Quiet Function

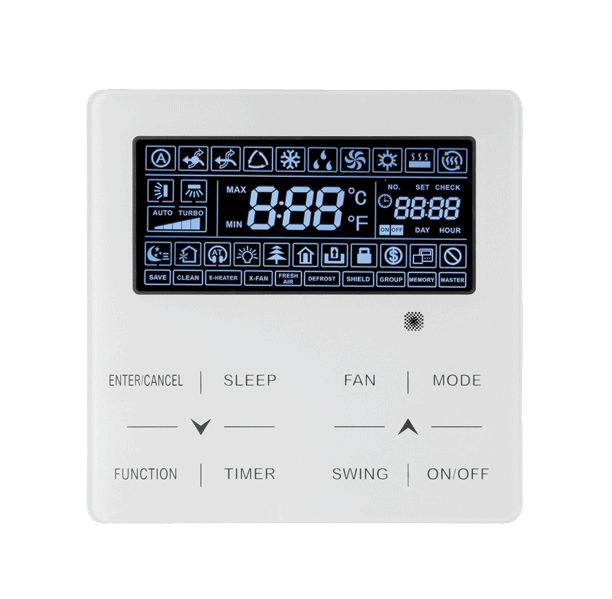

• Individual Control

• More Energy Saving

• Wide Operation Range

• Modules Rotation Operating

• Anticorrosive Golden Fins

• Compact Design

• Easy Maintenance

TVRF Heat Recovery System embodies the excellent features of TVRF Heat Recovery (DC inverter technology, DC fan linkage control, precise control of capacity output, balancing control of refrigerant, original oil balancing technology with high pressure chamber, high-efficiency output control, low-temperature operation control technology, super heating technology, high adaptability for project, environmental refrigerant).

Its energy efficiency is improved by 78% compared with conventional multi VRF.

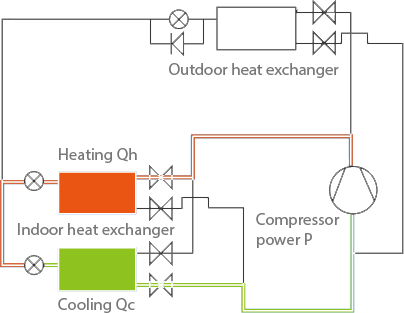

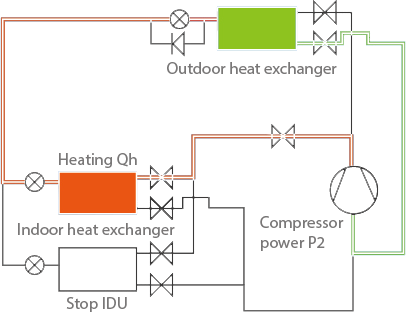

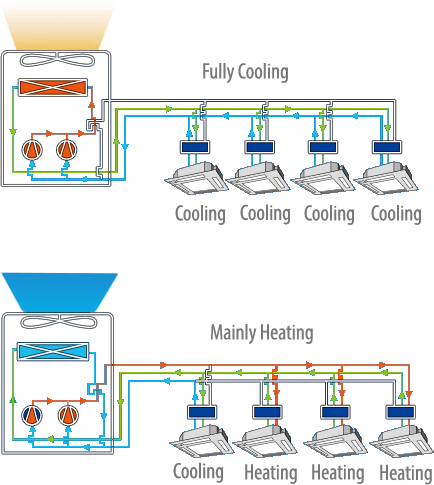

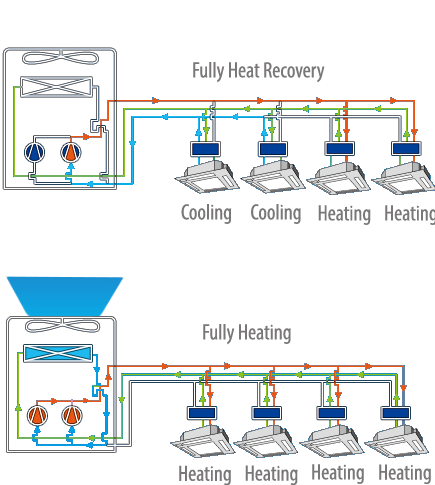

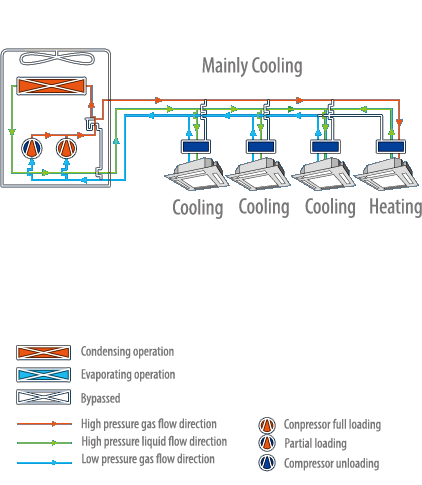

• Five Efficient Operation Modes

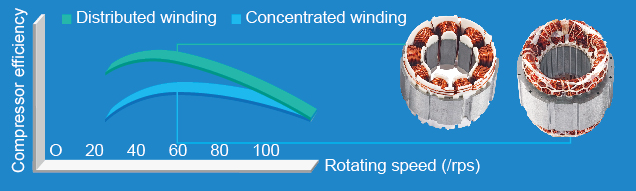

All DC Inverter Technology to Improve Compression Efficiency

• All DC inverter compressor is used in this system. It can directly intake gas to reduce loss of overheat and improve efficiency.

• High-efficient permasyn motor is adopted to provide better performance than traditional DC inverter compressor.

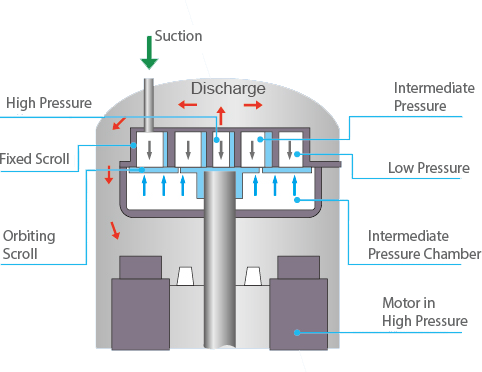

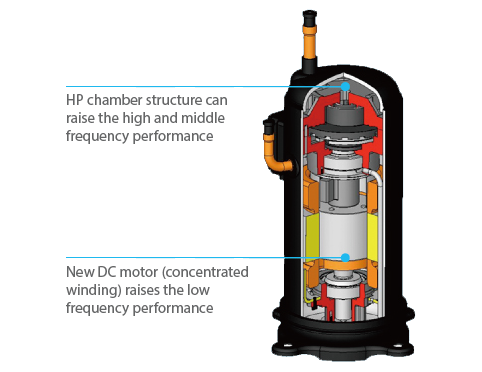

• High Pressure Chamber Design

What’s high pressure chamber?

The low-temperature and low-pressure refrigerant gas inhaled from the suction inlet of compressor will change to high-temperature and high-pressure gas after compression by scroll plate. Then the gas will go out from the exhaust at the center of fixed scroll and get into the lower chamber of compressor, so that the chamber of compressor is in high temperature and high pressure.

What’s the benefits of high pressure chamber?

High pressure chamber compressor inhales directly to reduce overheat suction loss and improve compression efficiency.

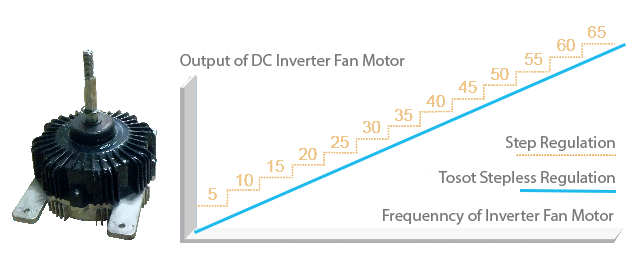

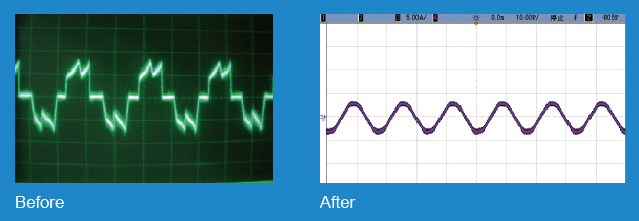

• Sensorless DC Inverter Fan Motor Stepless speed regulation ranges from 5Hz to 65Hz_Compared with traditional inverter motors, the operation is more energy-saving.

Sensorless control technology guarantees lower noise, less vibration and steadier operation.

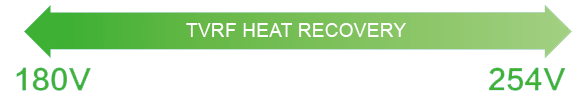

Wide Range of Voltage to Ensure a Steady System Running

Working voltage range of TVRF Heat Recovery system has been improved to 180V-254V. For places with unsteady voltage, this system can still be running well.

Wider Applicable Location

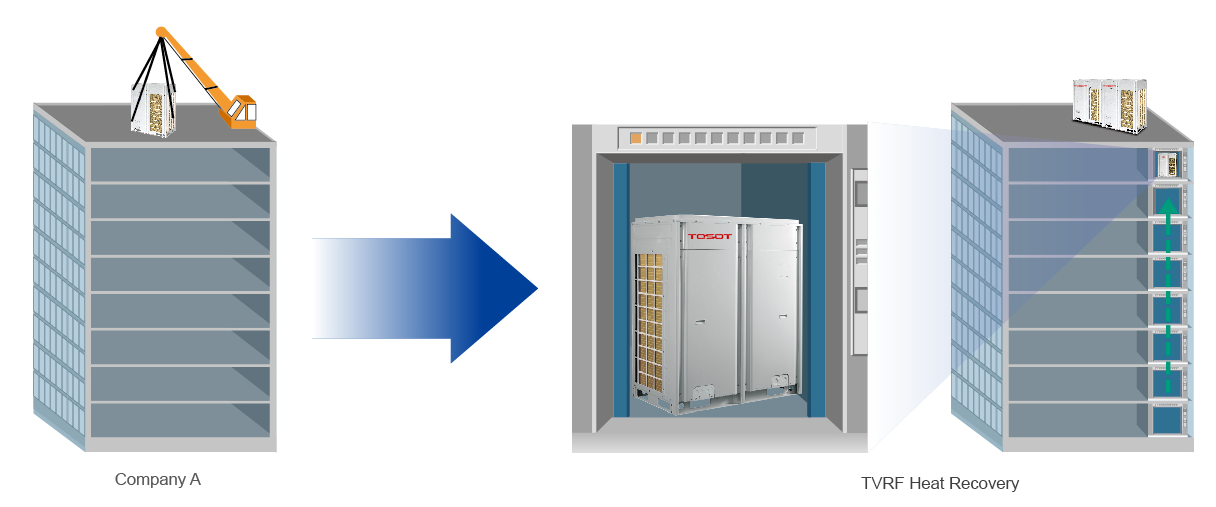

TVRF Heat Recovery can realize a combination of 3 outdoor unit modules connecting with as many as 61 indoor units. It’s especially applicable for business building or hotels.

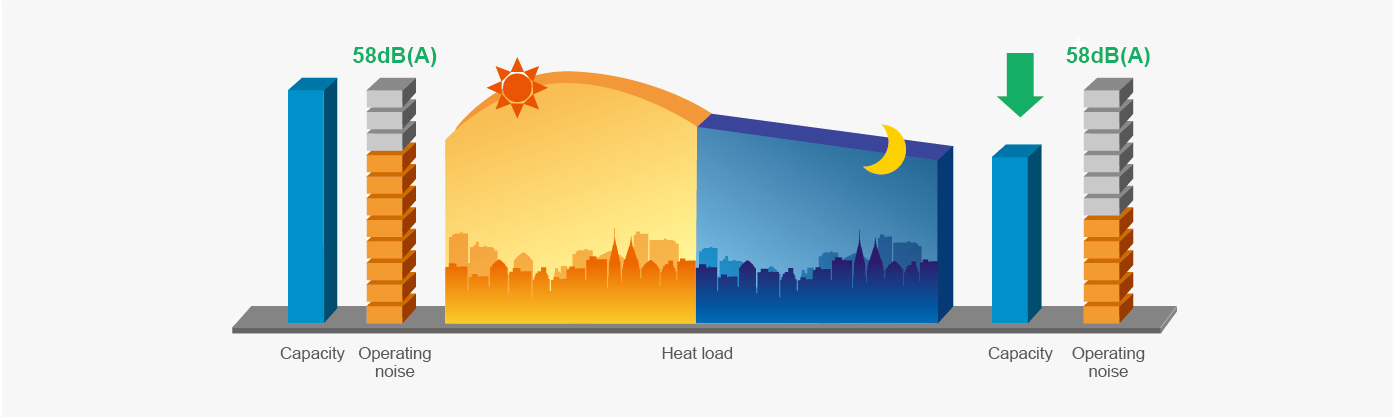

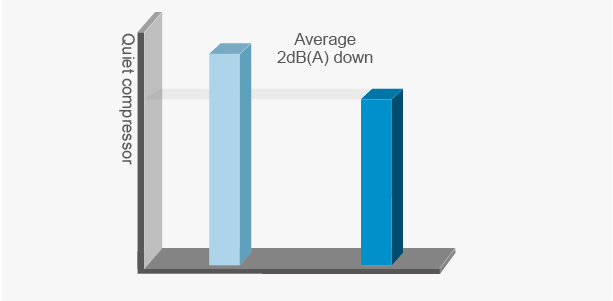

Intelligent Quiet Function at Night

• Quiet at night

Intelligently adjustment of outdoor fan control can minimize the noise during night time. Up to 8dB(A) can be reduced and operation noise at night is as low as 50dB(A).

• Low noise design

HP Chamber compressor has lower exhaust pressure fluctuation so that noise is lower.

The optimized design of condensing fan blade reduces the air flow turbulence among blades, so that the noise is lower.

Individual Control for More Energy Saving

The set temperature of each room may vary by the individual thermostat control of each indoor unit. The cooling and heating operation can be performed at the same time.

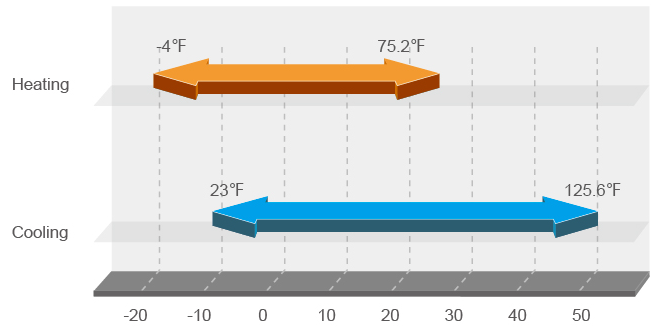

Wide Operation Range

The unit can operates in wide range, greatly reducing the ambient temperature limitation.

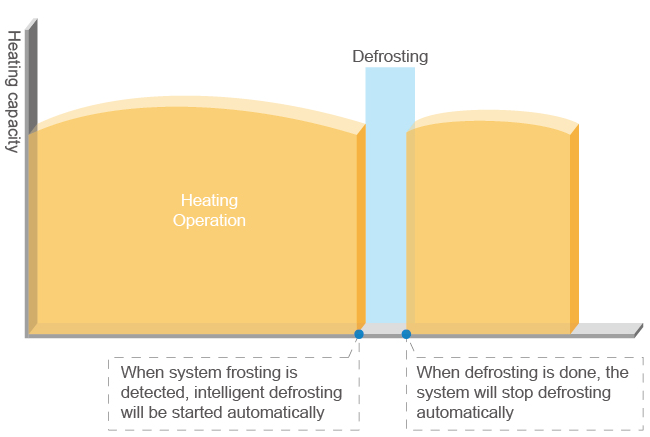

Comfortable Heating

Advanced intelligent defrosting mode is adopted. Tosot advanced intelligent defrosting mode will choose the best defrosting way according to outdoor temperature and operation status to realize intelligent defrosting, effectively improving heating effect and performance. While in traditional defrosting mode, timing defrosting is adopted, which not only comfort but also reduces energy efficiency.

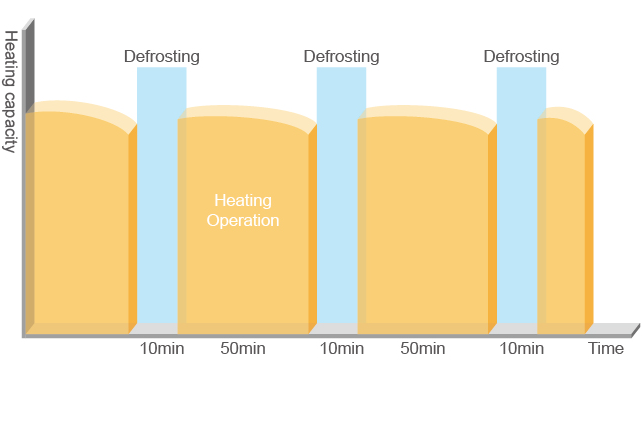

Traditional Defrosting Mode

Tosot Intelligent Defrosting Mode

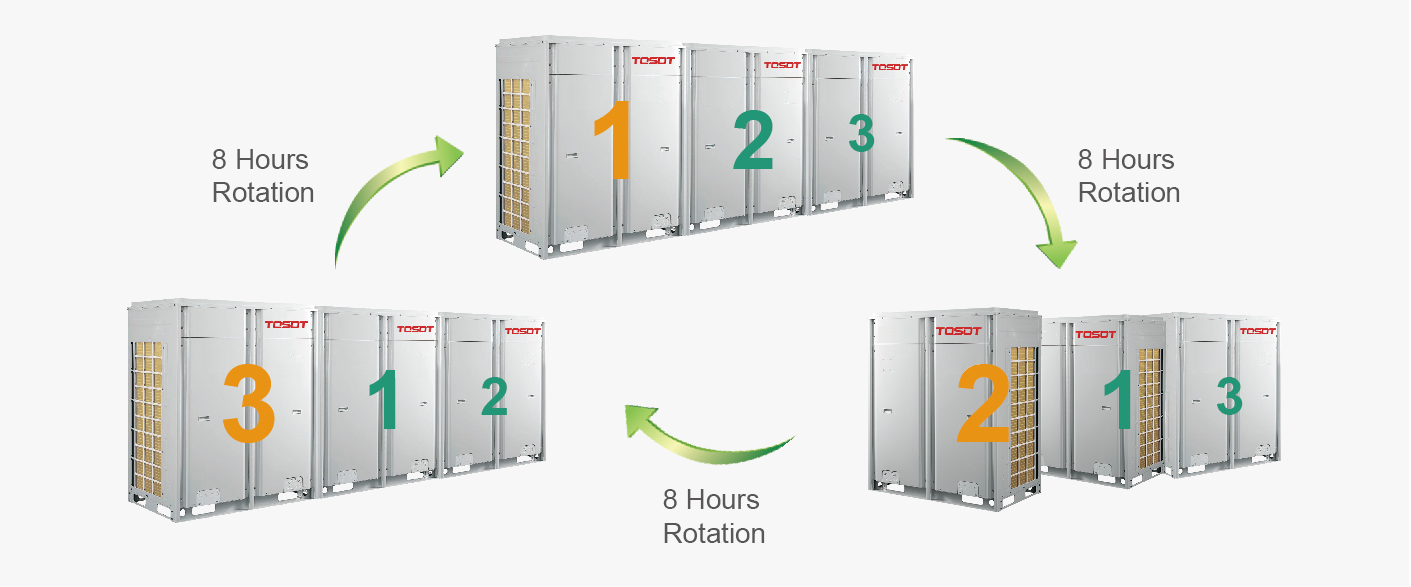

Modules Rotation Operating to Maximize Lifespan

• Modules 8h rotation operating

The operating priority sequence of the outdoor unit modules will be changed without restart when the system accumulatively operates for 8 hours, which can maximize the service life of the system.

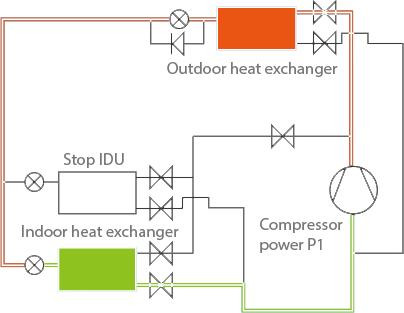

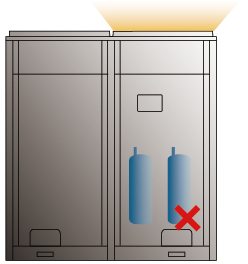

Excellent Emergency Operation Function to Ensure Reliable Operation

• Emergency Function

The TVRF Heat Pump system can realize a combination of 3 outdoor unit modules. When error is occurred to one of the modules, the others will perform the emergency operation to sustain the air conditioning.

• Emergency Operation of Compressor

All the compressors in each single module are DC Inverter based, when one compressor has error, others will perform the emergency operation.

• Emergency Operation of Fan

Double-fan design fan ensures that one fan can still work even if the other one has error.

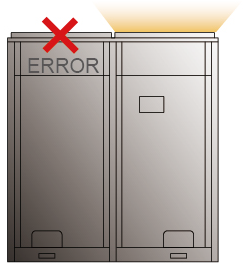

Highly Anticorrosive Golden Fins

The primary material of Golden Fin is Al-Mn(Alu-mium-Manganese) anti-rust alloy, which is coated with the Golden Protection Layer(Components: Epoxy Resin & Modified Acrylic, Silicon free), the anti-corrosive performance in salt-spray testing is 200%-300% higher than normal Blue Fin*.

Oil Return Control Technology

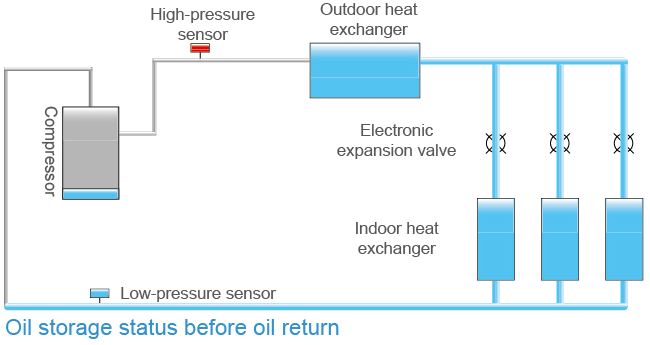

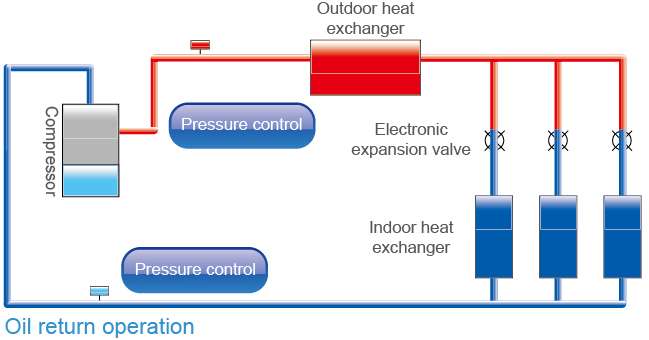

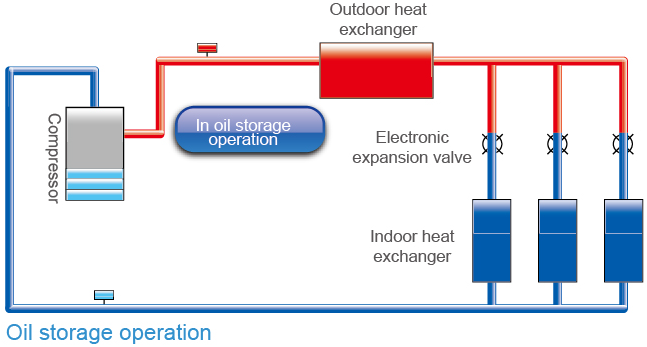

• New Oil Return Control

Tosot new oil return control technology effectively controls system oil return and oil storage status of each compressor, which greatly improves the operation lifespan of compressor.

• Specialized Compressor Oil Storage Control

The system applies specialized compressor oil storage technology, which can control the lowest oil level for compressor operation.

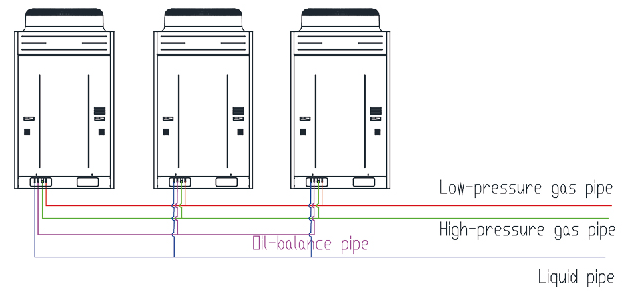

Without External Oil-balanced Pipe Design

The unit is without external oil-balanced pipe design, reducing system pipeline connection and easy for engineering installation. The system will allocate lubricating oil of each module according to its demand, which is more intelligent, more efficient and more equal.

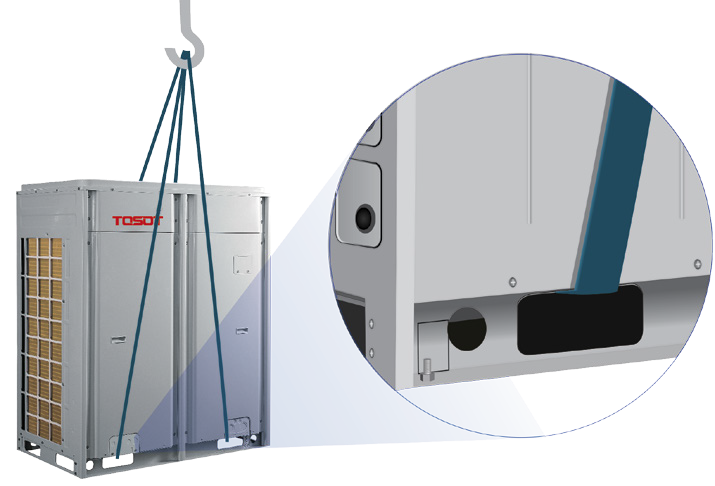

Compact Design

With compact design, the outdoor unit can be carried to the roof of building through elevator, with no need of crane. It is easier for delivery and installation.

Easy Transportation

Optimized base frame, the locating and fixing of the outdoor unit during installation is more convenient and reliable.

• Transportable by forklift

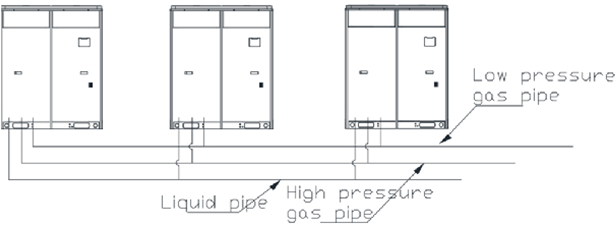

Piping and wiring are available to the front and back, left and right, and bottom.The five-way piping connection reduces installation difficulty and cost, improves the installation efficiency.

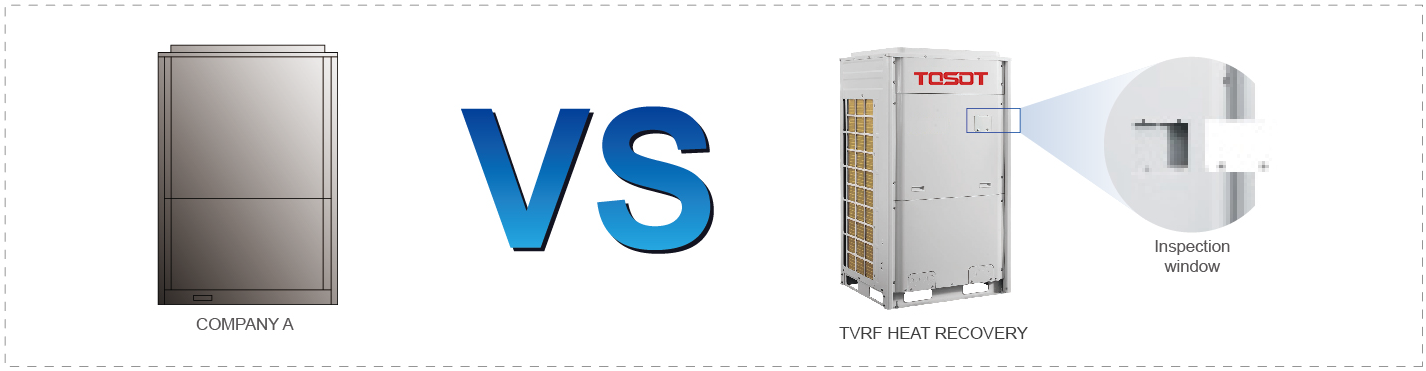

Easy Maintenance

• Inspection window is available for quick checking of system operation status. No need to open panel for checking, which will be more time-saving and easier for maintenance.

• Error Display & Self-diagnostic Function

Through LED display (different combinations of ON, OFF, or BLINK) on the main board, the malfunction can be judged.

| Models Outdoor Unit | TVRF- SHC72K/220V | TVRF- SHC96K/220V | TVRF- SHC120K/220V | ||

| Capacity | Ton | 6 | 8 | 10 | |

| Capacity | Cooling | Btu/h | 72,000 | 96,000 | 120,000 |

| Heating | Btu/h | 81,000 | 108,000 | 135,000 | |

| Power Supply | V/Ph/Hz | 208/230V~3~60Hz | 208/230V~3~60Hz | 208/230V~3~60Hz | |

| EER – IEER (Ducted/Non-Ducted) | 12/12 – 21.5/25 | 11.2/11.2 – 20.5/23.5 | 11/11 – 19/21 | ||

| High COP 47°F (Ducted/Non-Ducted) | 3.5 / 3.5 | 3.5 / 3.5 | 3.3 / 3.3 | ||

| MOCP | A | 50 | 60 | 80 | |

| Rated Current | A | 35 | 39 | 62 | |

| Maximum drive IDU NO. | unit | 12 | 16 | 20 | |

| Refrigerant Charge Volume | Oz | 336 | 384 | 416 | |

| Airflow | CFM | 8,240 | 8,240 | 8,240 | |

| Sound Pressure Level | dB(A) | 61 | 62 | 63 | |

| Operating Ambient Temperature Range | Cooling | °F | 23 ~ 125.6 | 23 ~ 125.6 | 23 ~ 125.6 |

| Heating | °F | -4 ~ 75.2 | -4 ~ 75.2 | -4 ~ 75.2 | |

| Piping connection | Liquid | inch | Φ3/8 | Φ3/8 | Φ1/2 |

| Gas(Low pressure) | inch | Φ3/4 | Φ7/8 | Φ1 1/8 | |

| Gas(High pressure) | inch | Φ5/8 | Φ3/4 | Φ3/4 | |

| Dimensions WxHxD | Outline | inch | 52-3/4×63-1/4×30-1/8 | 52-3/4×63-1/4×30-1/8 | 52-3/4×63-1/4×30-1/8 |

| Net/Gross Weight | Lbs | 666/699 | 683/716 | 794/827 | |

| Loading Quantity | 40’HQ | set | 16 | 16 | 16 |

Specifications of Branch

| Model | TVRF-SHCBU1T1 | TVRF-SHCBU1T2 | TVRF-SHCBU1T4 | TVRF-SHCBU1T8 | ||

|

|

|||||

| Max IDU Branches | / | 1 | 2 | 4 | 8 | |

| No. Of connectable IDU of each branch | / | 8 | 8 | 8 | 8 | |

| Total Connectable IDU | / | 8 | 16 | 32 | 64 | |

| Max. Capacity of each branch | Btu/h | 48,000 | 48,000 | 48,000 | 48,000 | |

| Max. Capacity of connectable IDU | Btu/h | 48,000 | 96,000 | 153,000 | 232,000 | |

| Power Supply | V/Ph/Hz | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | 208-230/1/60 | |

| MOCP | A | 15 | 15 | 15 | 15 | |

| Outdoor Unit Piping Connection | Liquid | in. | 3/8 | 3/8 | 1/2 | 5/8 |

| GasLow Pressure | in. | 7/8 | 7/8 | 1-1/8 | 1-1/8 | |

| GasHigh Pressure | in. | 5/8 | 3/4 | 3/4 | 7/8 | |

| Indoor Unit Piping Connection | Liquid | in. | 3/8 | 3/8 | 3/8 | 3/8 |

| Gas | in. | 5/8 | 5/8 | 5/8 | 5/8 | |

Outdoor Unit Combinations

| Model | Power Supply | Capacity | Dimensions (WxDxH) | Airflow | ESP | |

| Cooling | Heating | |||||

| V/Ph/Hz | Btu/h | Btu/h | In. | CFM | in.W.G | |

| TVRF-SHC144K/220V | 208/230V~3~60Hz | 144,000 | 162,000 | (52-3/4×30-1/8×63-1/5) x 2 | 8,240 x 2 | 0.33 |

| TVRF-SHC168K/220V | 208/230V~3~60Hz | 168,000 | 189,000 | (52-3/4×30-1/8×63-1/5) x 2 | 8,240 x 2 | 0.33 |

| TVRF-SHC192K/220V | 208/230V~3~60Hz | 192,000 | 216,000 | (52-3/4×30-1/8×63-1/5) x 2 | 8,240 x 2 | 0.33 |

| TVRF-SHC216K/220V | 208/230V~3~60Hz | 216,000 | 243,000 | (52-3/4×30-1/8×63-1/5) x 2 | 8,240 x 2 | 0.33 |

| TVRF-SHC240K/220V | 208/230V~3~60Hz | 240,000 | 270,000 | (52-3/4×30-1/8×63-1/5) x 2 | 8,240 x 2 | 0.33 |

| TVRF-SHC264K/220V | 208/230V~3~60Hz | 264,000 | 297,000 | (52-3/4×30-1/8×63-1/5) x 3 | 8,240 x 3 | 0.33 |

| TVRF-SHC288K/220V | 208/230V~3~60Hz | 280,000 | 324,000 | (52-3/4×30-1/8×63-1/5) x 3 | 8,240 x 3 | 0.33 |

| TVRF-SHC312K/220V | 208/230V~3~60Hz | 312,000 | 351,000 | (52-3/4×30-1/8×63-1/5) x 3 | 8,240 x 3 | 0.33 |

| TVRF-SHC336K/220V | 208/230V~3~60Hz | 336,000 | 378,000 | (52-3/4×30-1/8×63-1/5) x 3 | 8,240 x 3 | 0.33 |

| TVRF-SHC360K/220V | 208/230V~3~60Hz | 360,000 | 405,000 | (52-3/4×30-1/8×63-1/5) x 3 | 8,240 x 3 | 0.33 |