Mini VRF

Mini VRF

-

3 Ton to 5 Ton

VRF

Features

• Comfortable and Quiet Mode

• Intelligent Temperature Control

• Reliable Operation

• Anti-interference Ability

• Ultra-long Connection Pipe

AHRI Certificate

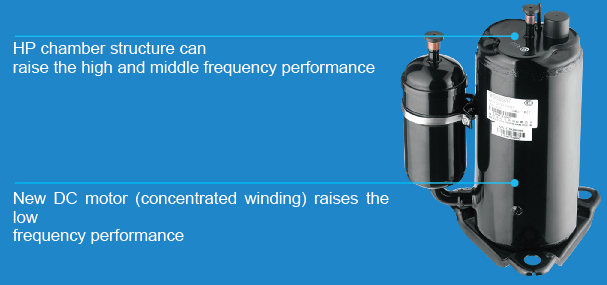

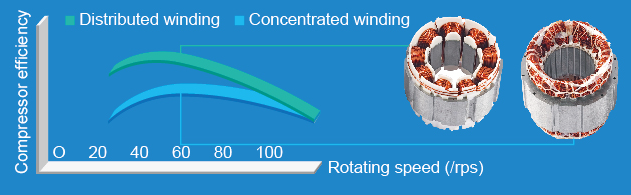

All DC inverter compressor and high-performance high pressure chamber are adopted to reduce loss of overheat and improve compression efficiency from direct intake. Compared with low pressure chamber, the compression efficiency is improved. High-efficient permasyn motor is adopted to provide better performance than traditional DC inverter compressor.

• All DC inverter compressor is used in this system. It can directly intake gas to reduce loss of overheat and improve efficiency.

• High-efficient permasyn motor is adopted to improve better performance than traditional DC inverter compressor.

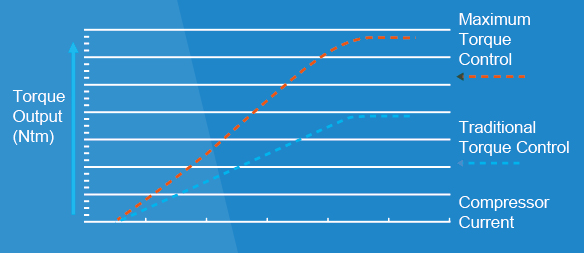

• Technology of Maximum Torque Control with Minimum Current

It can reduce energy loss caused by device winding so as to realize higher efficiency.

• Low-frequency Torque Control

It can directly control motor torque, through which fan motor can run at a low speed. Users will feel more comfortable while requirements of the system are also met.

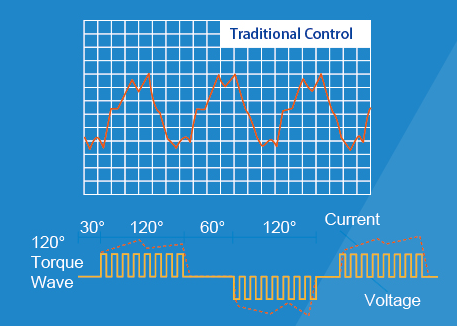

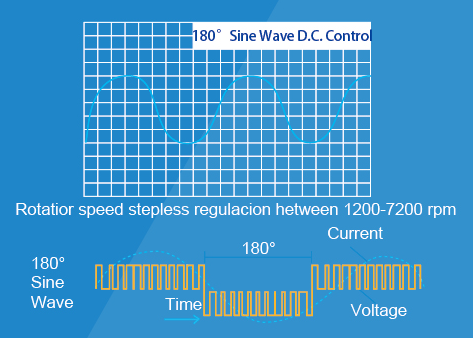

• 180° Since Wave DC Speed Varying Technology

It can satisfy various places and demands for different temperature and is able to save a great deal of electricity and provide users with utmost comfort at the same time.

Sensorless DC Inverter Fan Motor

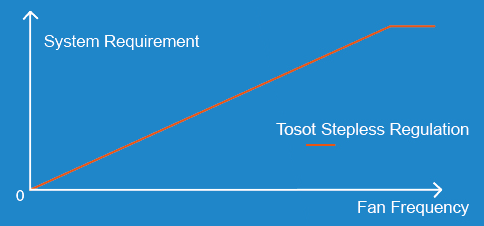

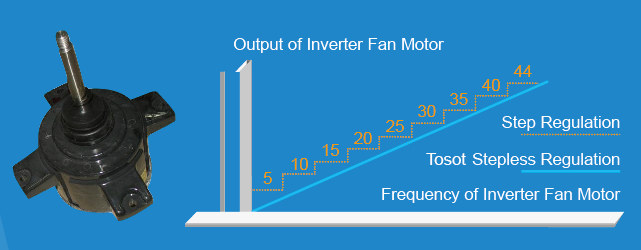

• Stepless speed regulation ranges from 5Hz to 44Hz. Compared with traditional inverter motors, the operation is more energy-saving.

• Sensorless control technology guarantees lower noise, less vibration and operation.

Sensorless DC Inverter Fan Motor

The indoor unit adopts high-efficiency brushless DC motor. Compared with conventional motor, the efficiency of brushless DC motor is improved by more than 30%. Meanwhile, the design of evaporation capacity flow is optimized through emulation software of refrigeration system and the heat exchange amount of evaporator is greatly improved.

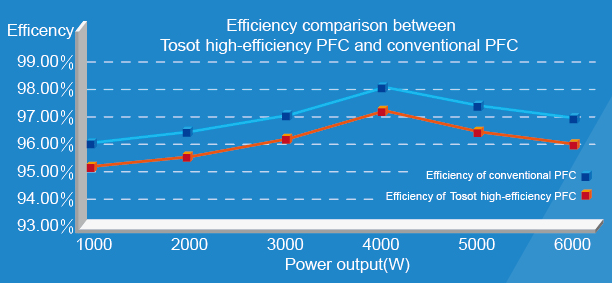

High-efficiency Digital PFC Control

High-efficiency PFC control technology is adopted with efficiency improved by about 1% compared with conventional PFC. For the air conditioner with rated power of 5kW, 50W of electricity can be saved every hour and 1.2kW of electricity can be saved every day.

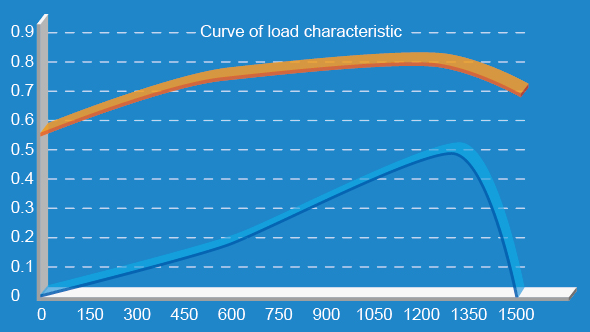

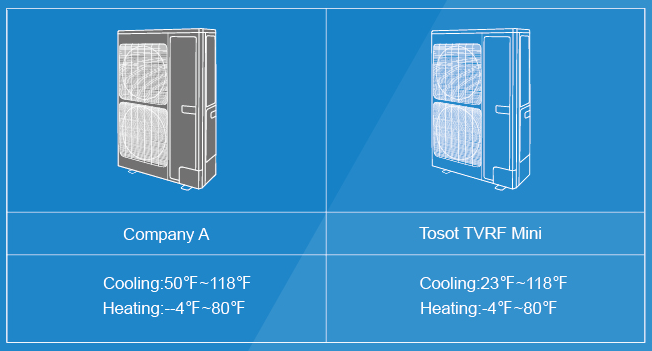

Wider Operation Condition Range

The unit adopts DC motor with more accurate high pressure control, which effectively solves the high pressure control problem in low ambient temperature cooling. So the operation range in cooling is wider.

Low Noise of Outdoor Unit

• The advanced sub-cooling control technology is applied to reduce the liquid flow noise of indoor unit in cooling operation.

• Noise of outdoor unit can be as low as 45dB thanks to noise optimized design or fan system and compressor system, and multiple kinds of quiet modes of outdoor unit.

Low Noise of Indoor Unit

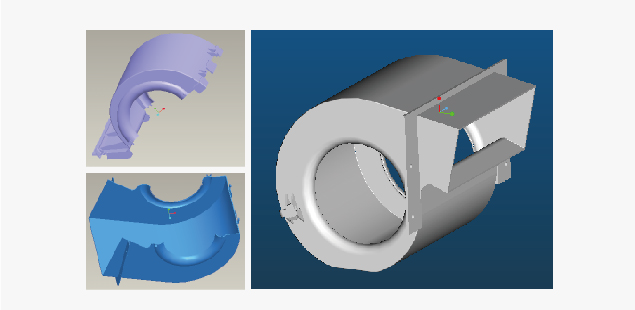

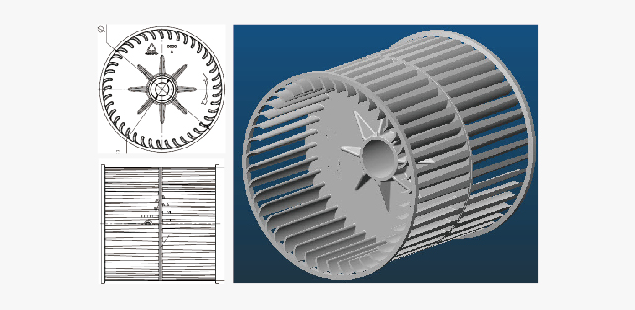

• The pioneering and patented high-efficiency centrifugal fan blade and low-noise volute are adopted. Meanwhile, the imported silent valve is adopted to reduce noise of entire unit as low as 22db(A).

• By adopting the optimal inlet angle of centrifugal fan blade and optimal diameter ratio between internal and external circles of impeller, the air volume is increased and fan noise is decreased greatly.

• The advanced supercooling control technology and the oil-return technology under heating mode has efficiently solved the problem of liquid flow noise of indoor unit , which improved the sound quality of indoor unit.

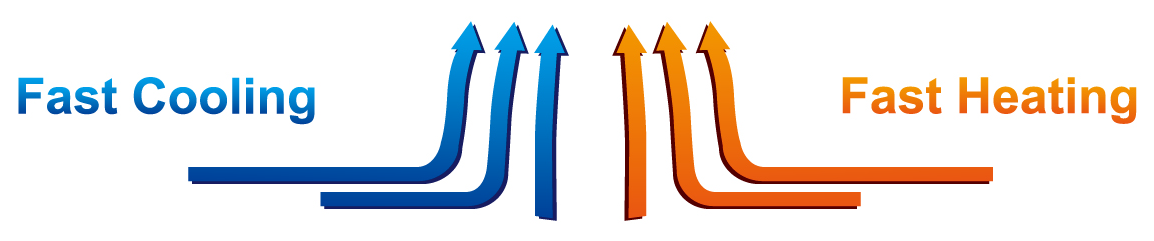

Intelligent Temperature Control Technology

Intelligent temperature control technology is adopted for super fast cooling or heating, so that indoor temperature will reach set temperature more quickly.

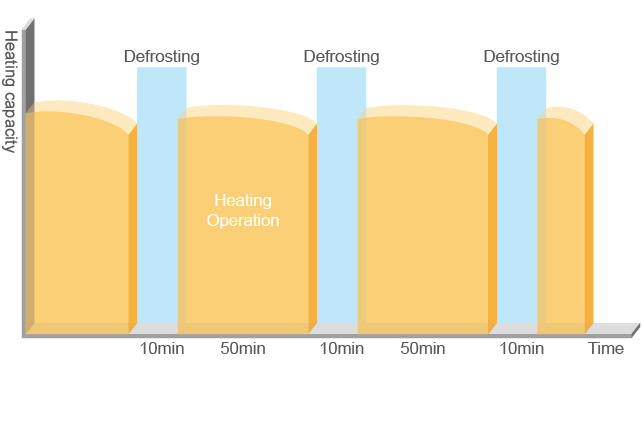

Comfortable Heating

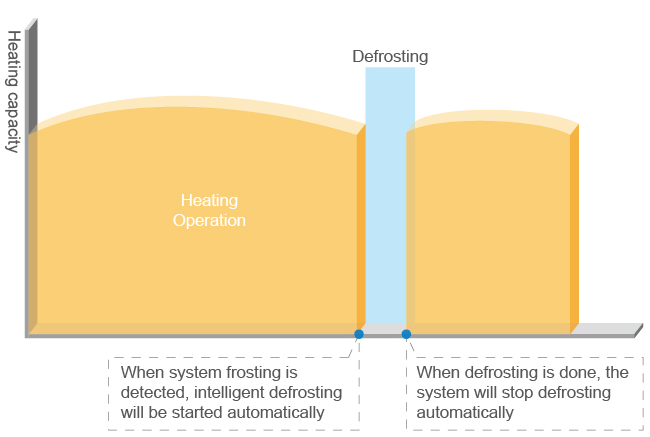

Advanced intelligent defrosting mode is adopted. Tosot advanced intelligent defrosting mode will choose the best defrosting way according to outdoor temperature and operation status to realize intelligent defrosting, effectively improving heating effect and performance. While in traditional defrosting mode, timing defrosting is adopted, which not only affects comfort but also reduces energy efficiency.

Traditional Defrosting Mode

Tosot Intelligent Defrosting Mode

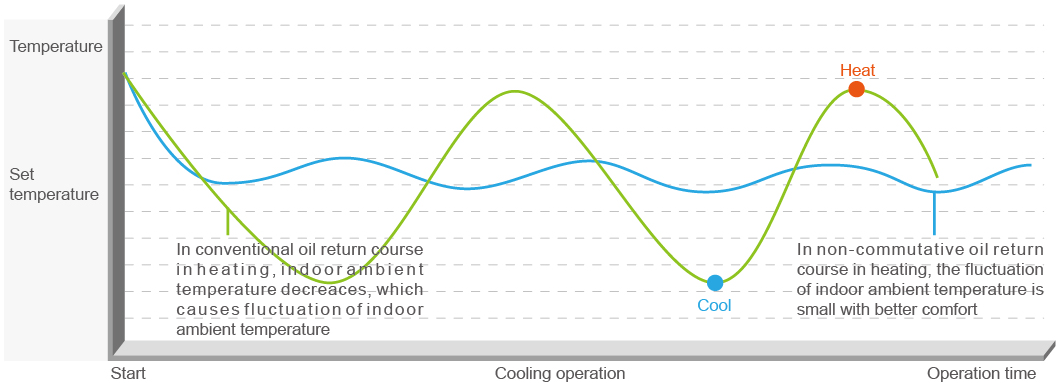

Non-commutative Oil Return Technology in Heating

The unit can achieve non-commutative oil return in heating when outdoor ambient temperature is within 0-20°C. Thanks to this technology, indoor ambient temperature is more stable and comfort is improved in heating mode.

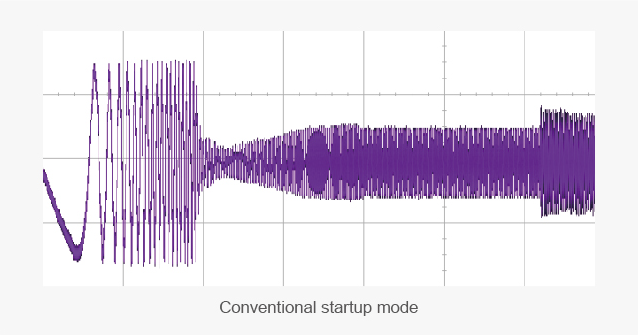

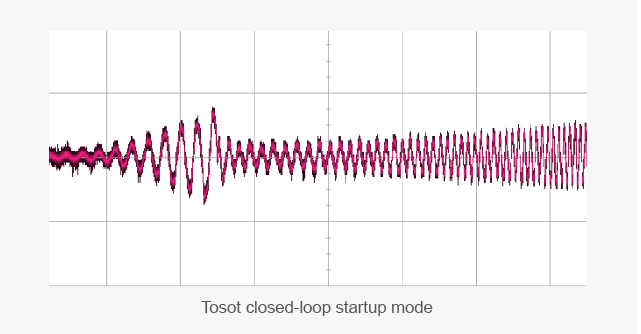

Compressor Closed-loop Startup Technology with More Reliable Startup

The self-innovative closed-loop startup control technology is adopted. Thanks to this technology, the startup current is small and startup is more reliable.

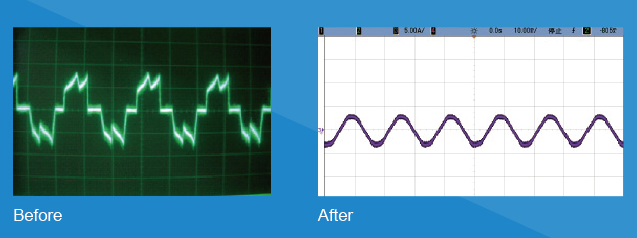

High Anti-interference Ability

The latest CAN bus communication technology is adopted, with non-polar communication and high anti-interference ability. Common communication wire can meet the communication demand with no need of specialized shielded wire. The customers can buy the communication wire by themselves, greatly reducing installation difficulties.

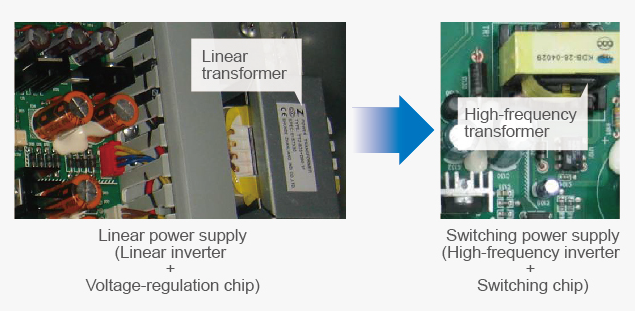

Advanced High-frequency Transformer with More Stable Voltage

• The advanced switching power supply is adopted with lower power consumption and higher power efficiency.

• Wide voltage-regulation range ensures stable voltage output when the voltage of grid fluctuates.

• Compared with conventional transformer, the size of high-frequency transformer is small and the weight is light.

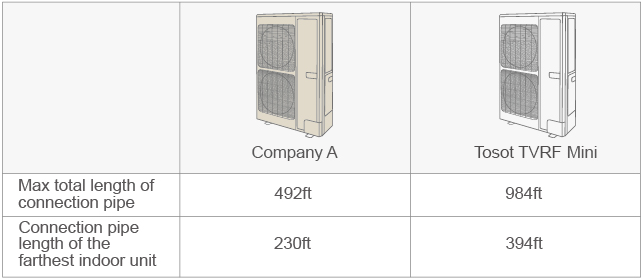

Ultra-long Connection Pipe for More Convenient Connection

Under the subcooling control technology gained by adding subcooler, the indoor unit and outdoor unit of TVRF mini can operate reliably with longer connection pipe.

| Models Outdoor Unit | TMVRF-OC36KHP | TMVRF-OC48KHP | TMVRF-OC60KHP | ||

| Capacity | Ton | 3 | 4 | 5 | |

| Capacity | Cooling | Btu/h | 37,500 | 48,000 | 60,000 |

| Heating | Btu/h | 42,000 | 54,000 | 66,000 | |

| SEER (Ducted/Non-Ducted) | 16 / 16 | 16 / 16 | 16 / 16 | ||

| HSPF (Ducted/Non-Ducted) | 9 / 9 | 9 / 9 | 8.2 / 8.2 | ||

| MOCP | A | 50 | 60 | 70 | |

| Rated Current | A | 32 | 37 | 42 | |

| Power Supply | V/Ph/Hz | 208/230V~1~60Hz | 208/230V~1~60Hz | 208/230V~1~60Hz | |

| Maximum drive IDU NO. | unit | 5 | 7 | 9 | |

| Airflow | CFM | 3,531 | 3,708 | 4,590 | |

| Refrigerant Charge Volume | Oz | 176.4 | 176.4 | 229.3 | |

| Piping connection | Liquid | inch | Φ 3/8 | Φ 3/8 | Φ 3/8 |

| Gas | inch | Φ 5/8 | Φ 5/8 | Φ 5/8 | |

| Dimensions WxHxD | Outline | inch | 35-3/8 x 53 x 13-3/8 | 35-3/8 x 53 x 13-3/8 | 35-3/8 x 53 x 13-3/8 |

| Net/Gross Weight | Lbs | 242.6 / 264.6 | 242.6 / 264.6 | 273.4 / 299.9 | |

| Loading Quantity | 40’HQ | set | 60 | 60 | 57 |